-

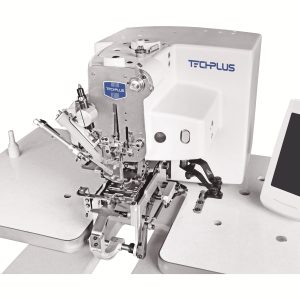

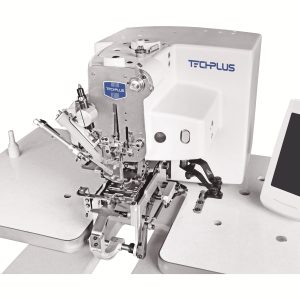

Features Adapt to different direct drive or Computer button sewing machines, such as 373D, 438D, 1903A, etc; Sewing area: 8-28mm, Special ordered range can reach 5-35mm. Suitable for 4-hole button, 2-hole button and three hole buttons or other non-standard buttons; Each machine standard with 14 different mounting plates, to replace 2 screws easily for positioning…

-

Features High speed: It can cut 70~90 pcs per minute. (50mm long) Accuracy: Cut-length is accurate owing to a stepping motor. Cutting type: Melting & cutting by hot knife, woven label is cut neatly without fraying but not for heavy materials and installed with anti-static electricity device. Automatic operation: It works automatically only by setting…

-

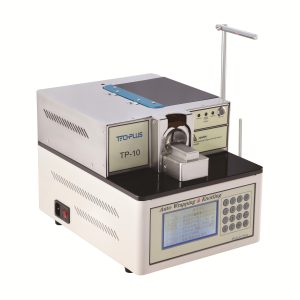

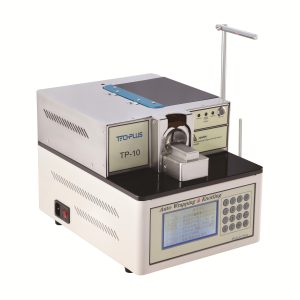

Features Fully automatic button wrapping machine suited for all large volume factories. Wrapping at high speed with constant precision, and 360 degree heat sealing ensure button lifetime security. Wrapping, sealing and finishing each button shank only takes about 1 second. Has three programs to be preset, enable fast switching from one shank style to another….

-

Features Use advanced LQD iWMtoring control system. Easy operation, no need skilled workers. Automatic thread trimmer, and Most simple mechanical devices. Common thread, Imitation manual knotting. Wrapping Max .Speed can reach 2500rpm. Three knotting in the end, Max 130 stitches. No need oil, No need needle. Application for Suits / Shirts / Trousers / Jackets…

-

-

-

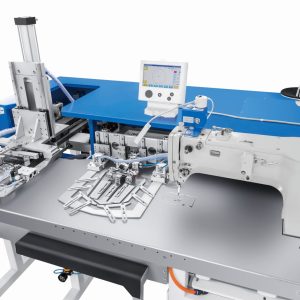

Features Sleeve setting operations is one of the most important procedures of garment sewing. This machine is professional and efficient for setting sleeves, mainly applicable for man’s suit, overcoat, business wear etc. Digital controlled on upper sleeves sewing process. 360 sewing process of one sleeve can be divided into several sections. The corresponding puckering values…

-

Features TP-313 use for doubel side stitch, it have special blind stitch sewing method and the special double stitching hemming design. TP-316 use for different kind of thick material’s blind stitch sewing. The accuracy and evenness of the blind sewing can be under control with the special vertical feeding method Technical Parameter

-

End Control By Reflecting Light Barrier Automatic Folding Collection Device (Patented) Features Constant sewing results on different fabrics. Automatic seam end control either by seam length measurement or reflecting light barrier. Fully overlapped working, easy to operation, short training period. Four various top-stitch widths available with quick adjustment. Folding tochnique independent from the fabric….

-

Features Standard configuration has included: matching strip materials, put side labels, Vacuum positioning function which can freely adjust the vacuum strength according to different materials by holding the panel. With functions automatic folding, automatic feeding, automatic collecting, automatic start stitching and thread breakage detecting, Etc. Normal working efficiency: 5-6pcs pocket/minute. Technical Parameter

-

Features Use 311G/326/342G sewing machine head, applicable for welting all kinds of pockets, fake pockets, T shirt plancket, especially for Sweatshirt Zip pockets, can be finished one time automatically. Its 3 times more efficient than normal pocket welting machine. The automatic non-ironing folding mechanism adopt full automatic cylinder folding technology, which improve the productivity and…

-

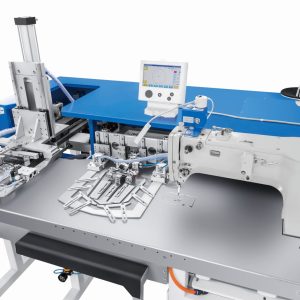

Features The machine supports the sewing of straight pockts (with flaps) on suits, jackets and pants. Double-/single-welt sewing can be changed over by the simple touch of a key on the operation panel. Extended sewing length (18mm~220mm). With flap Sigle welt/double welt Technical Parameter

-

Features Reasonable and compact structure, large heating area, even temperature, precise tempreature control. Convenient speed, pressure sensitive. Low noise, and easy maintenance changer. Is a garment manufacturing enterprises applicable professional equipnent. QSL typeis lower belt longer, QS for the two roll twopressure. Technical Parameter

-

Features Postbed construction for easy handling of work pieces; Fullness distribution by means of bottom feed, needle feed and alternating foot top feed; Integrated fullness control and stitch loosening device (manually or automatically engage able) for constantly high quality; Edge trimmer (Class TP-697-24155) with various trimming margins available; Robust and durable design Technical Parameter

-

Features Honeycomb board is more flat Dual rail beam is more stable Suction cup adsorption is more strong Technical Parameter